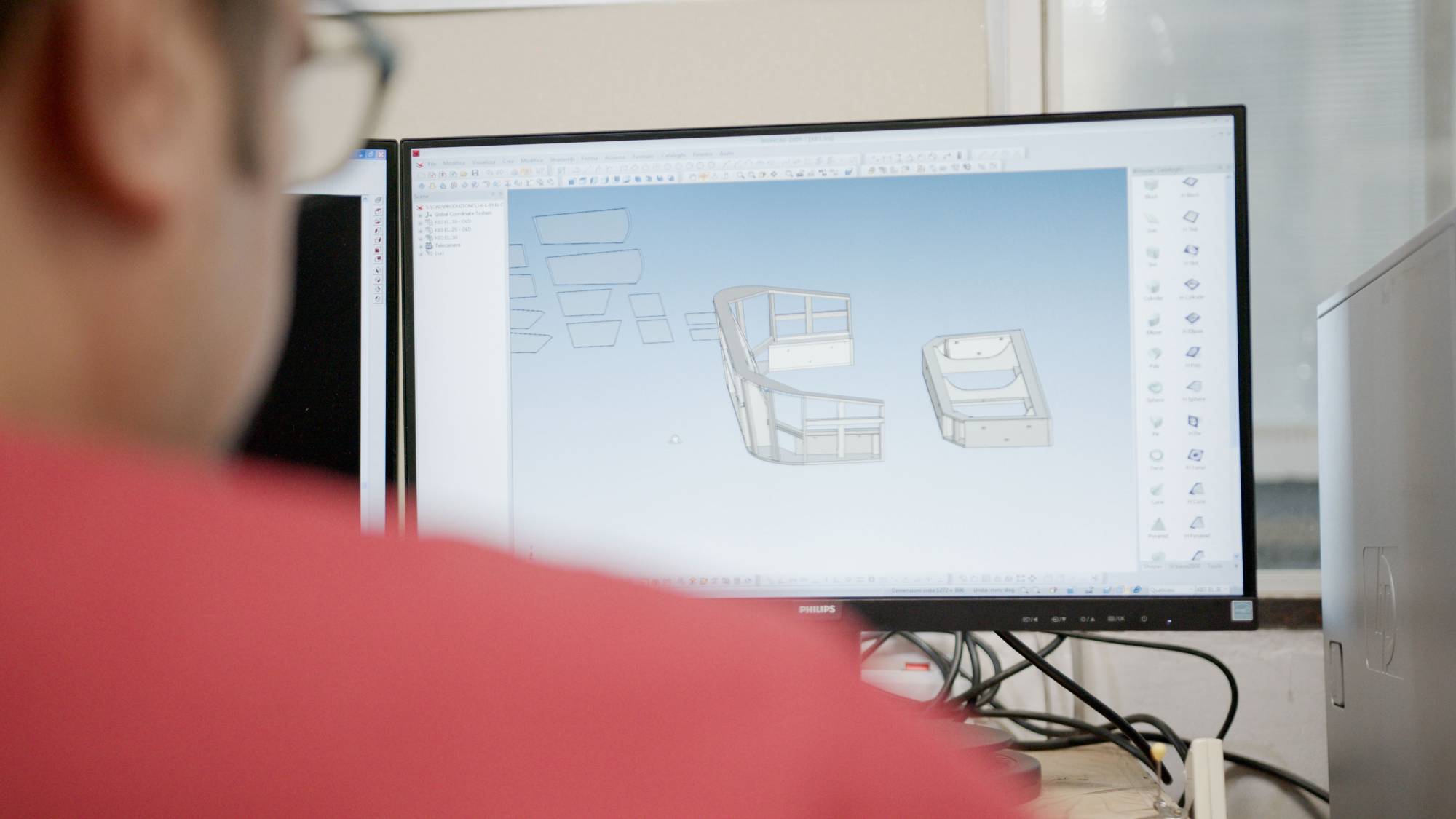

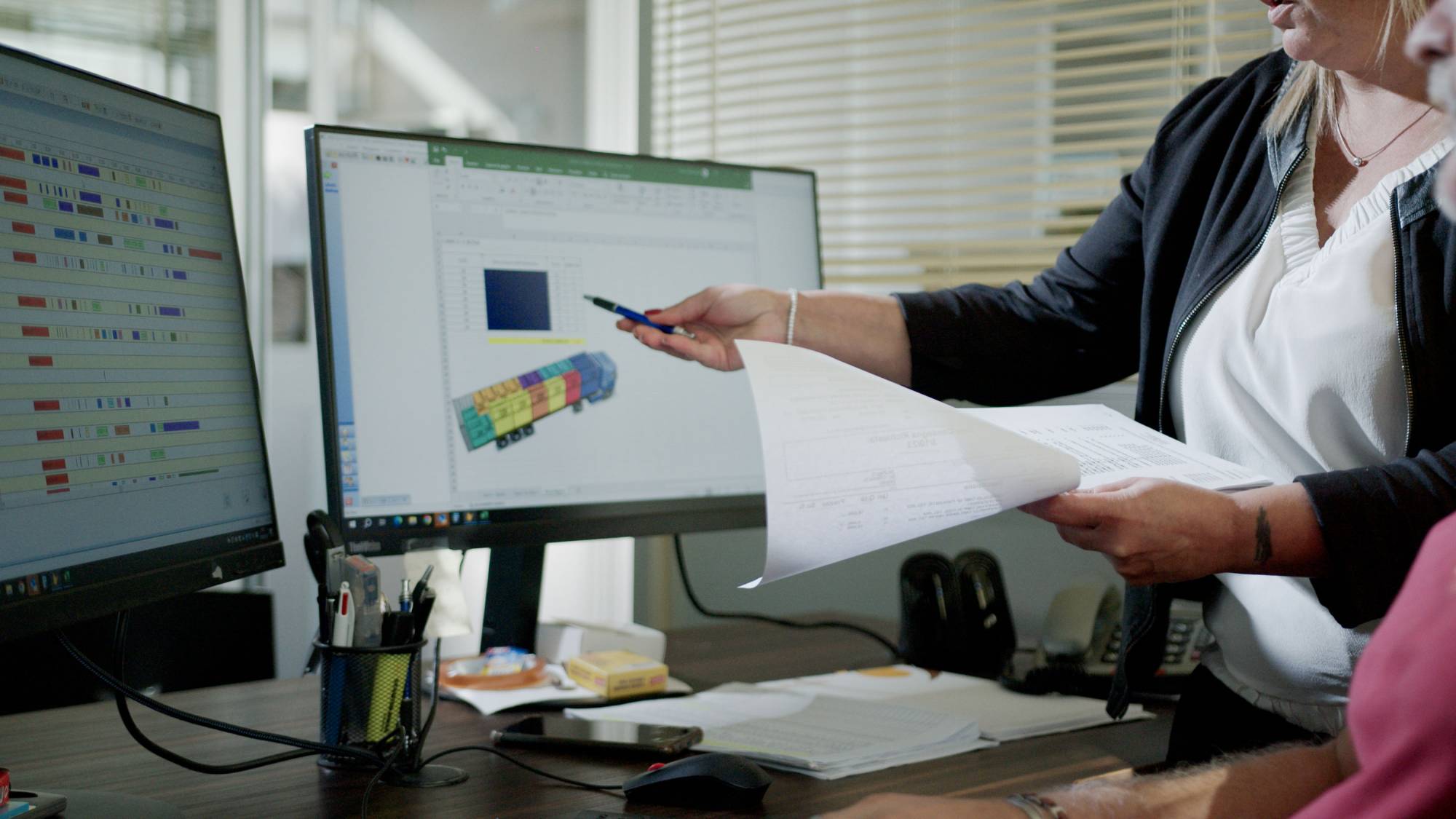

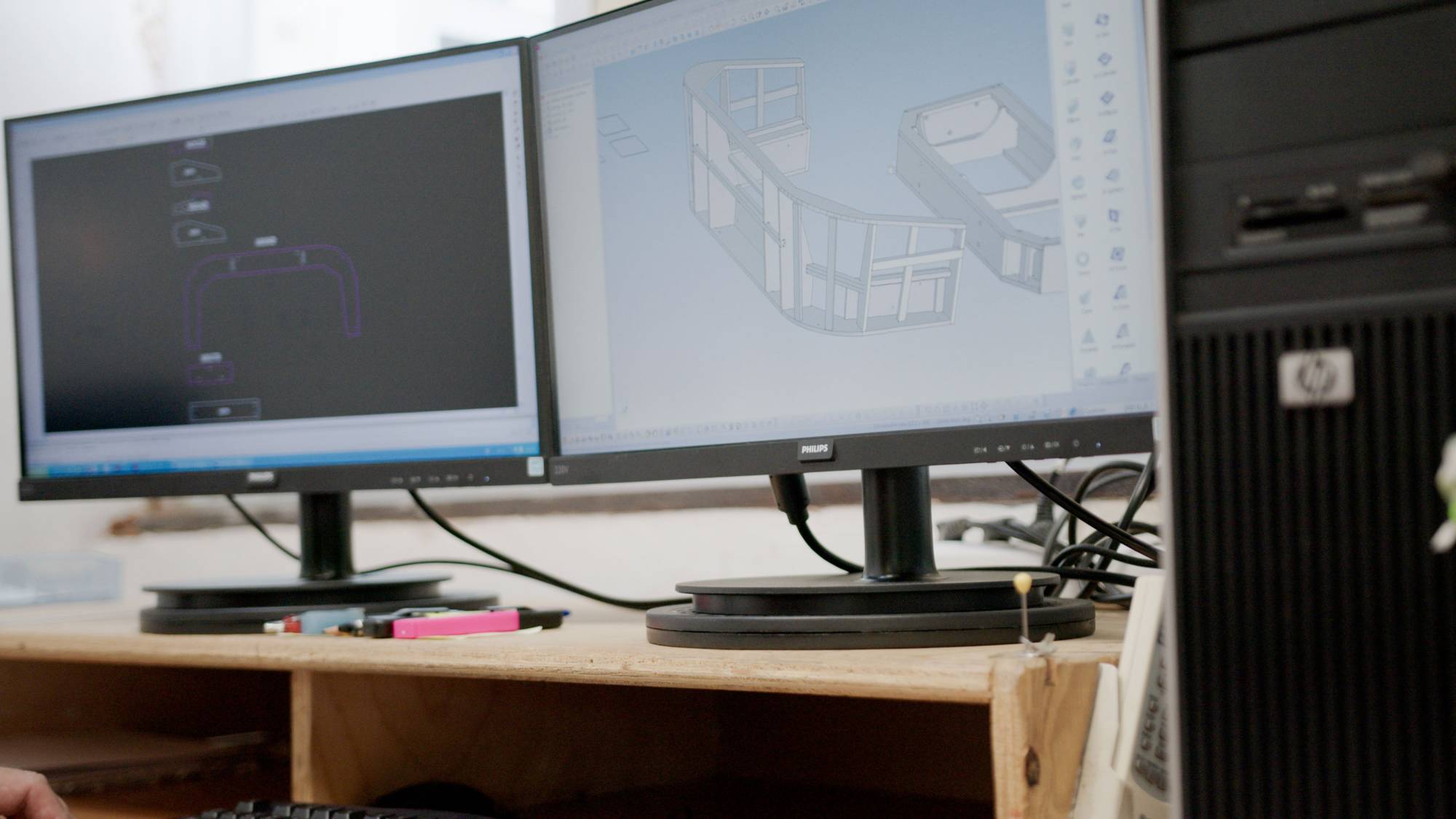

Engineering

The design phase represents a point of excellence due to an advanced and integrated approach. The technical design office, consisting of three experts, coordinates the control of in-house machining. Thanks to an automated system, monitoring is extended throughout the entire production cycle. This synergy enables optimization of processes and timing, thus helping to raise the company's overall efficiency.